Rely on the Building Science Experts

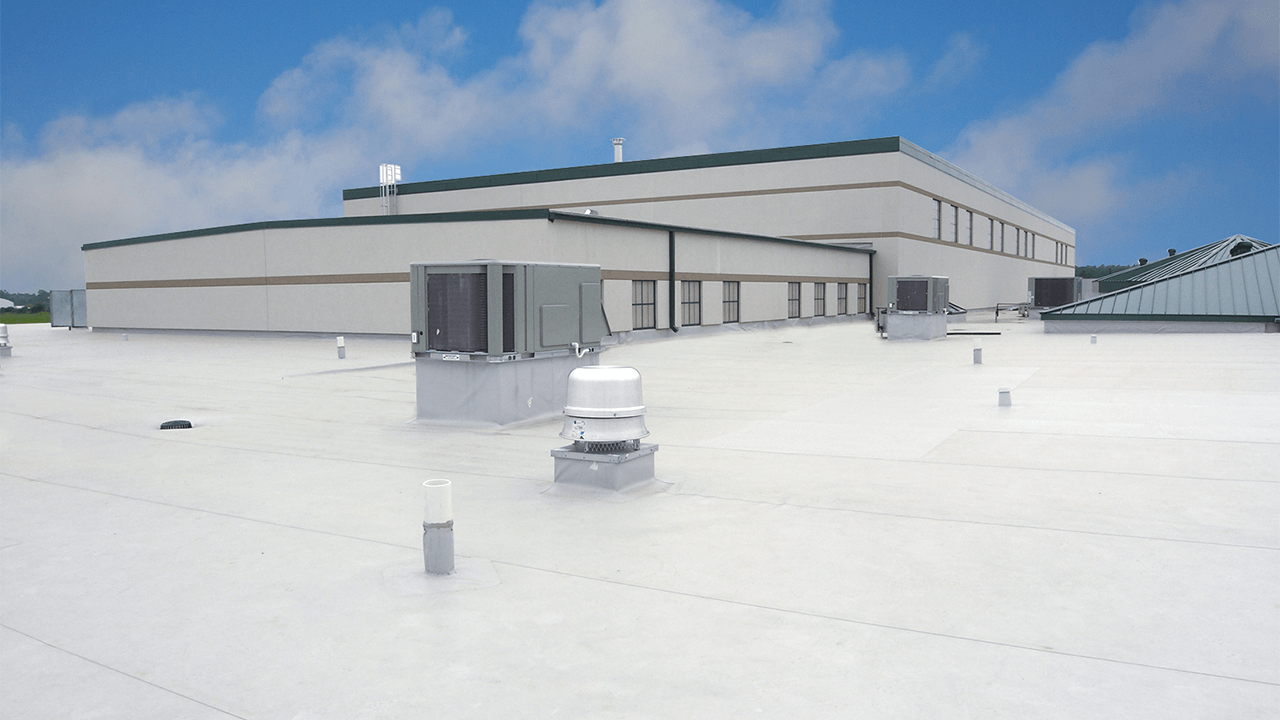

Duro-Last has been the industry leader in producing custom-fabricated single-ply roofing systems, designing each roof to fit building specifications exactly, and manufacturing it under controlled factory conditions.Single-Ply Duro-Last® Roofing Systems

The World's Best Roof®

Duro-Last has been the industry leader in producing custom-fabricated single-ply roofing systems, designing each roof to fit building specifications exactly, and manufacturing it under controlled factory conditions.

Advantages of Duro-Last

Watch our commercial about Duro-Last Roofing

For building owners and managers, Duro-Last's custom fabrication of single-ply roofing systems offers several advantages:

Studies of roof failures show that most problems occur because of installation errors, particularly at changes in plane on the roof, such as projections, curbs, drains, perimeters and abutting walls. Duro-Last prefabrication eliminates up to 85% of on-site, rooftop membrane seaming, greatly reducing the likelihood of installation errors and leak problems in the future.

Prefabricated roofing systems are easier to install throughout the year, even during adverse weather conditions. Installation time is reduced so the contractor can get on and off the job quickly. The relatively small amount of roof membrane seaming done in the field is completed with hot-air welding methods, which are virtually unaffected by cold or damp weather conditions.

Single-ply roofing prefabrication dramatically reduces waste, both during the manufacturing process and installation. The roofing contractor orders the exact amount of roof membrane necessary for roof coverage, rather than a collection of raw materials.

Prefabrication also appeals to engineers and architects who would like to address a particular structural or aesthetic design problem. Panel sizes, shapes and colors can be pre-planned and prefabricated to achieve desired visual results.

Finally, prefabrication allows the roofing contractor to take control of a construction operation in a highly unstable environment. Roofing contractors must plan their roofing projects carefully, and are rewarded with greater worker productivity, a higher-quality installation and more satisfied customers.

The Duro-Last Single-Ply Roof Membrane

Peace Of MindDuro-Last has been approved by Factory Mutual as a 1-60,1-75, 1-90, 1-95, 1-105, 1-135, 1-150, 1-165, 1-195, 1-210, 1-270, 1-435, and 1-495 roofing system. Duro-Last is also listed by Underwriters Laboratories as a Class A, B, & C approved material.

The Duro-Last vinyl roof membrane is a proprietary thermoplastic formulation consisting of PVC resins, plasticizers, stabilizers, biocides, flame retardants and U.V. absorbents. A weft-insertion knitted scrim that is laminated between two layers of PVC film gives the membrane its strength and durability. The Duro-Last single-ply membrane is available in white, gray, dark gray, tan, or terra cotta.

Our flexible roof membrane is easily prefabricated into deck sheets up to 2,500 square feet in size, as well as custom-made parapet, stack, and curb flashings that eliminate most labor from critical roof areas - transitions and changes of plane. Prefabrication provides architects, specifiers, consultants, contractors, and building owners peace-of-mind regarding the watertight security of the roof installation.

Duro-Last has met or exceeded all major fire and wind code requirements, and regional approvals as necessary throughout the country. These certifications reinforce Duro-Last's leadership in providing the consistent, watertight integrity that building owners expect.

Duro-Last has been approved by Factory Mutual as a 1-60,1-75, 1-90, 1-95, 1-105, 1-135, 1-150, 1-165, 1-195, 1-210, 1-270, 1-435, and 1-495 roofing system. Duro-Last is also listed by Underwriters Laboratories as a Class A, B, & C approved material. Evaluation services ICBO and NES have merged to form ICC-ES, which has evaluated Duro-Last for the International Building Code (IBC). The Duro-Last roofing system has been approved by the IBC and by code agency MIAMI-DADE for use in their respective jurisdictions.

Duro-Last is proud to be a charter partner of the ENERGY STAR® Roof Products Program. The ENERGY STAR label indicates to building owners and managers that the Duro-Last white vinyl roof membrane can save them money on cooling costs due to its high reflectivity (reflects 88% of the sun's energy). Duro-Last is also a charter member of the Cool Roof Rating Council (CRRC) and a member of the United States Green Building Council (USGBC). Duro-Last participates in all major technical committees in the roofing industry, plus the American Society of Testing Materials (ASTM).

Compare the FACTS

| Duro-Last | Manufacturer A | Manufacturer B | Manufacturer C | |

| Membrane Type | PVC | TPO | EPDM | Modified Bitumen |

| Custom Prefabricated Deck Sheets? | Yes | No | No | No |

| Sheet Construction | Factory prefabricated into panels up to 2,500 sq. ft | Roll goods only. 500 sq. ft. coverage per typical roll | Roll goods only. 1,000 sq. ft. coverage per typical roll | Roll goods only. 100 sq. ft. coverage per typical roll |

| All Flashing Material Reinforced | Yes | No | No | No |

| Flashing Method | All heat-welded | Glue & heat-welded | Glue | Hot mopped |

| Curbs & Stacks Custom Prefabricated? | Yes | No | No | No |

| Scuppers and Parapets Custom Prefabricated? | Yes | No | No | No |

| Coverage For Ponding Water? | Yes | No. Typically voids warranty | No. Typically voids warranty | No. Typically voids warranty |

| Coverage for Consequential Damages | Yes | No | No | No |

| Warranty Coverage | Repair or replacement | Repair only | Repair only | Repair only |

| Warranty Provided At No Extra Cost? | Yes | No | No | No |

Why Choose Us?

- Constant Owner interaction means no project manager or multiple people trying to make decisions.

- The highest quality products and with many small details that often go unnoticed by other contractors, let's take your roof project to the next level.

- Quality Control. The owner is hands on throughout the project, if any problems or issues arise they can be dealt with immediately.

- Nonstop communication - The key to the success of your project is good communication. And, a big part of communication is listening. From the beginning of a project to its end, our company places a high priority on listening - to you, your needs and wishes.

- Solid Science - Our Building Science experts understand the principles of heat, air and moisture flow, and how the building envelope interacts with a building's mechanical systems as well as its occupants.